We always enjoy receiving Weekend CNC Warrior submissions and we REALLY enjoy getting them from our already "approved" Weekend CNC Warriors. It really shows the excitement they have in using our projects over and over again. Thanks to Tom, Suzanne, Keith and Uncle Henry for submitting these projects to help inspire and keep the creative juices going!

Tom Watson

(Watson's Wooden Words)

"Here is a recent carving from the Pop’s tool shop. It is carved in 1 ½” western red cedar."

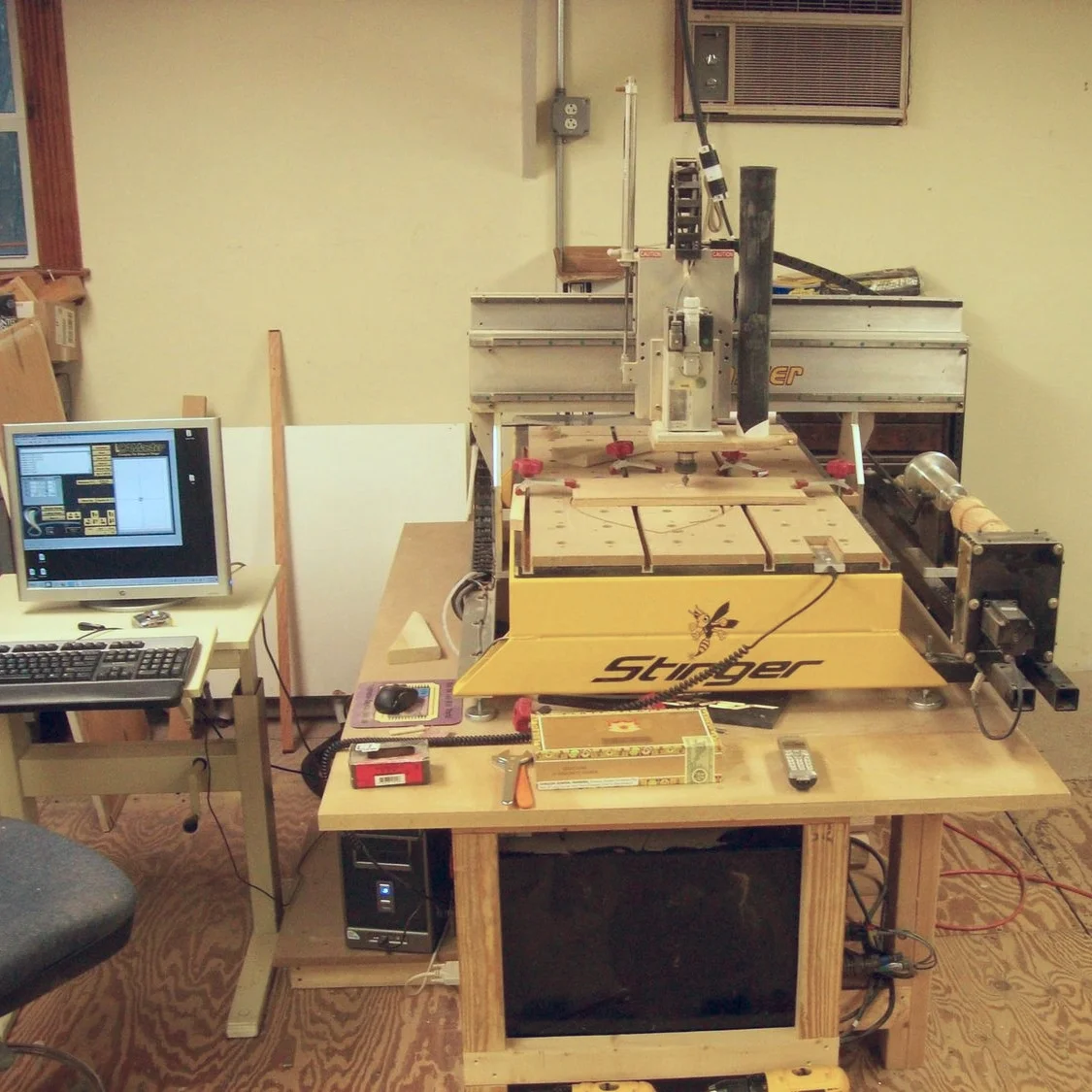

"It was painted with blended FolkArt paint. Carved on my The Pilot Pro CNC using Vectric Aspire software."

Tom used Pop's Tool Shop No.1 to create this beautifully finished layout and what a great saying!

Tom sent us this shortly after last years Vectric User Group Meeting. Great work Tom! We hope to see you again this year at the 2015 event!

Tom used our Halloween No.2 project for this layout.

Tom had a busy Christmas, last year, making trivet candle holders.

With a finished piece looking like this you can see why.

Tom used the Home for the Holidays No.2 project to create these festive candle holders.

If you are interested in Tom's other projects check out his official Shop Notes post where you can see more of his work and find out more about Watson's Wooden Words.

Suzanne Ramsey

(Suzanne's Woodworking)

What a great holiday decoration created using the Toy Soldier from the Home for the Holidays No.1 project!

Candle holder centerpiece hack using the Home for the Holidays No.2 project!

Suzanne has a knack for coming up with some pretty impressive layouts using our projects.

She has a great eye when it comes to hacking together some of our models with models in her library.

Raw part just before Suzanne adds the finish.

Interested in other Weekend CNC Warrior projects Suzanne made or how to find her on the internet?

Check out her official Shop Notes post for all kinds of inspiration and other great information about Suzanne's Wood Working.

Another great hack using models from the Home for the Holidays No.1 and what a great finish!

Keith Geiger

This is a great hack from Keith. He used the plaque shape from the Pick-Up League Basketball project and added some raised text and a logo. If you look close you can see he incorporated in a mustang car model he picked up from Vector Art 3D.

Great work Keith!

For more of what Keith has been doing with our projects check out his official Shop Notes post.

Super job!

Uncle Henry

Rendering in Aspire

Finished Piece - NICE!

"Here is the plaque I made for my nephew. He is planning on going to study movie making in college."

Uncle Henry came up with a great layout using our Home Cinema No.1 project. We're thinking his nephew was pretty impressed with the finished piece!

Interested in what other projects Uncle Henry has created? Check out his official Shop Notes post for some great inspiration and information!

Thank you to all of our Weekend CNC Warriors that keep sending in the fantastic pictures of their projects! We appreciate all of the support and its work like yours that really shows off our projects, the power of a CNC through good craftsmanship, imagination and passion!

Get yourself officially Weekend CNC Warrior Approved... you know you deserve it!

Post it in the Vectric User Forum under Vector Art 3D / Design and Make It - Gallery or Email us an image of a project you made that uses one of our projects and a short description (try to include software used, the CNC ,finishing process and a social link... don't forget your name).

When it gets posted we will be sure to let you know!!!!

Be safe and let the chips fly!

The Design and Make/CNCProjects Team